SMART™ Thin Film Deposition Systems

Physical Vapor Deposition (PVD)

The Scientific Materials and Applied Research Tool (SMART) platform is a versatile deposition system that is engineered for today's thin films deposition research applications. The table top chamber can incorporate multiple deposition techniques including thermal evaporation sources, electron beam evaporation, sputter deposition, and pulsed laser deposition. The Ultra High Vacuum Deposition (UHV) configuration delivers a high purity environment for sensitive materials. The integrated control panel minimizes the laboratory footprint and provides convenient process control. Optional process monitoring techniques such as RHEED, quartz crystal monitor, and residual gas analyzer provide the researcher with real-time process information. The SMART Deposition System can be configured for a wide range of applications:

- Thin Film Deposition by evaporation or Sputter deposition

- Pulsed Laser Deposition

- Ohmic Contact Deposition and Annealing

- Ion Beam Etching

Sample Manipulators

The SMART Sample Manipulators are engineered for up to 3 inch diameter samples and are UHV compatible. The SVT Associates proprietary filament design allows for sample heating up to 800 °C in a variety of background pressure and gasses. Uniform deposition is ensured with sample rotation speeds up to 30rpm. Sample biasing is available upon request.

- Uniform Sample Heating Up To 800 °C

- UHV Compatible

- High Performance Ammonia and Oxygen compatible Models Available

Deposition Source Technology

SVT Associates draws on more than 15 years of process knowledge to provide a full line of deposition sources and techniques. The wide selection of sources ensure that SVT Associates has the combination to optimize your application.

- High Stability Effusion Cells (thermal evaporation source) for Ultra Controllable Deposition

- Multi-Pocket Electron Beam Evaporator for High Purity Low Vapor Pressure Materials

- Magnetron Sputtering Sources offer High Material Incorporation

- Three Material Boat Evaporator Delivers Rapid Deposition of Material

- RF-Plasma Source allows development of Oxide and Nitride Materials

- Pulsed Laser Deposition for Complex Oxides

- Ion Sources for Etching and IBAD Processes

In-Situ Process Monitoring

Control your deposition process with SVT Associates In-Situ Process Monitoring technology. The complete line of In-Situ Monitoring Tools provides real-time information and data logging to help you develop a highly reproducible process.

- 10 keV RHEED Source Provides Growth Rate and Material Quality Monitoring

- The RHEED Image Analysis Package Delivers Automated Information of Growth Process

- Integrated QCM for Growth Rate Monitoring

- RGA for Gas Analysis / Vacuum Diagnostics

Technical Documentation:

Contact SVTA for more information.

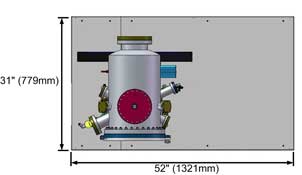

Top View of SMART System

|

Large Door Provides Easy Access to the Vacuum Chamber

|